Estimating is one of the most controversial subjects in project management. There are some people who have turned the subject into a cryptic science involving esoteric techniques.

Estimating is one of the most controversial subjects in project management. There are some people who have turned the subject into a cryptic science involving esoteric techniques.

Estimating is simply the process used to determine the amount of effort and cost required to implement a project, in part or in full. It is important to acknowledge that estimating is fundamentally an effort at projecting the future. Like all projections, the more facts and information available, the better the estimate. There is a natural human tendency to avoid making estimates because estimates represent commitments, and people tend to shy away from commitments, particularly when they are not sure of the facts. Nevertheless, little progress would be made if we never attempted to plan for the future.

Most estimating errors are errors of omission, not commission. It is what we forget to estimate that often leads to problems. Methodologies, with their defined structure, materially assists with eliminating some of the unknowns when estimating. They provide frameworks and structures acting as checklists for estimating. Methodologies isolate the activities to be performed into small enough increments, thereby minimizing the margin of error.

An estimate improves in accuracy in direct relation to the level of detail considered. A methodology defines the sequence of events by which parts are assembled. For example, a construction methodology identifies all of the resources of a product, such as lumber, steel, glass, etc. and how they are assembled. An Information Systems related methodology, such as “PRIDE”-ISEM, specifies the sequence by which data elements, records, files, inputs, outputs, processes, etc. are assembled.

This provides the ability to use a “bill of materials” (BOM) technique to count all of the resources in the product and develop an estimate for the project, in part or in full, based on the standards developed for completing and/or installing a resource. This is why “PRIDE” methodologies put an emphasis on “rough designs” in the early phases of work.

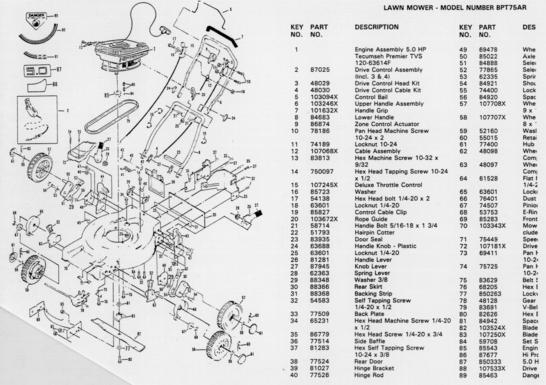

To better understand the BOM concept, consider all products are composed of a variety of parts, be it electronics, automobiles, airplanes, ships, bridges, skyscrapers, homes, etc. Using BOM, the various components are identified and related to the other parts they will be attached. To illustrate, here is a lawn mower showing all of the parts, identified by number and name, along with their relationships:

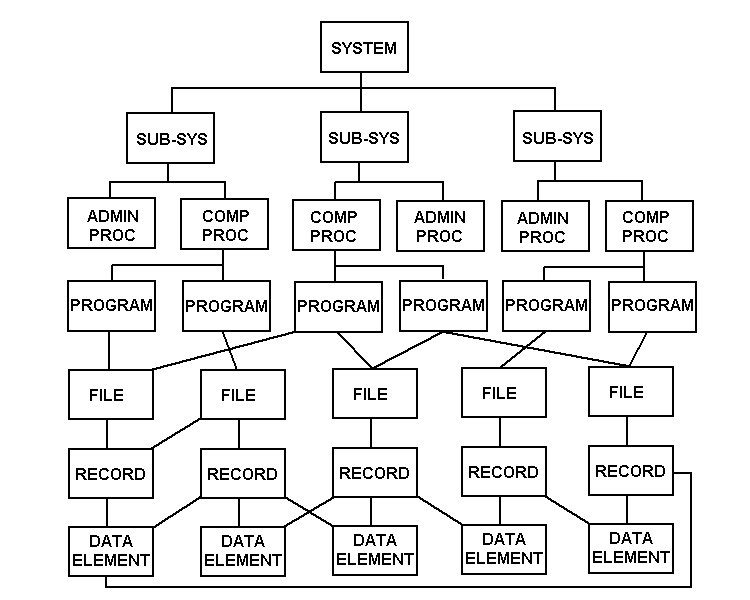

Such illustrations can typically be found in most product warranty guides. Obviously, BOM is an old concept used by engineers and architects for many years, but they can also be applied to information systems involving sub-systems (business processes), procedures (both administrative and computer), programs, files, inputs, outputs, records, and data elements. It can also be used in programming components, such as modules. To think of systems in this manner is somewhat of a revolutionary concept.

From such designs, the Project Manager is asked to consider:

* The number and types of NEW components to be created.

* The number and type of existing components requiring MODIFICATION.

* The number and type of existing components that can be RE-USED as is (no modification required).

To illustrate, in a “PRIDE”-ISEM Project (Phase 1), a complete “rough design” of the envisioned system is produced in Activity F. In Activity G, the Project Manager takes the rough design and makes the following type of assessment:

| COMPONENTS |

NEW |

MODIFY |

RE-USE |

| SYSTEM |

1 |

|

|

| SUB-SYSTEMS |

14 |

|

|

| ADMIN PROC |

23 |

|

|

| COMP PROC |

13 |

|

|

| PROGRAMS |

28 |

|

|

| MODULES |

33 |

10 |

112 |

| INPUTS |

17 |

|

5 |

| OUTPUTS |

37 |

13 |

|

| FILES |

56 |

5 |

43 |

| RECORDS |

250 |

50 |

306 |

| DATA ELEMENTS |

60 |

257 |

This analysis is essentially no different than other products consisting of different components, such as circuit boards, chips, nails, screws, lumber, girders, glass, gaskets, pistons, etc.

In systems, the rough design is used as the road map for the project (in the above example, there will have to be 14 Phases 3-7 because there are 14 sub-systems and 13 Phase 4-II & 6 for the 13 computer procedures, and at least 28 Phase 5’s for the programs). It is also the basis for the project estimate. Such estimating is greatly facilitated through the use of an IRM Repository which controls the components and, as such, acts like a Bill of Materials Processor (BOMP).

The BOM concept permits the establishment and application of estimating guidelines. To illustrate; how much direct time does it take to weld a six inch pipe? Define a data element? Design a sub-system? Such standards should be based on whole work (Direct Time) as opposed to including interferences (Indirect Time). Indirect time is a part of the work environment and can vary from company to company, group to group, even person to person. Estimating, therefore, must be accomplished using Direct hours only.

Having standards in place, we can then consider variations based on the skills of the worker. For example, how long it takes a novice worker to weld a product will certainly be longer than an expert. The same is true in systems analysis and programming. This is where a Skills Inventorycomes in handy to select the appropriate worker for a project assignment.

By making system designers build a rough design of the product early in a project, the bill of materials can be populated accordingly and greatly improve estimating accuracy. As the project progresses, and changes are identified in the product structure, revisions in estimates can be easily made.

This is all made possible by using an engineering/manufacturing approach in the design and development of products, including systems.

Keep the Faith!

Note: All trademarks both marked and unmarked belong to their respective companies.

Author: Tim Bryce, Managing Directory, M&JB Investment Company

Author: Tim Bryce, Managing Directory, M&JB Investment Company

Tim Bryce is a writer and the Managing Director of M&JB Investment Company (M&JB) of Palm Harbor, Florida and has over 30 years of experience in the management consulting field. He can be reached at[email protected]

Copyright © 2015 by Tim Bryce. All rights reserved.